More progress on the Z650

So an update on progress which has been up and down.

I didn’t fancy trying to fit the shock and new linkage myself so I booked it in at the local motorbike shop 100m away. They fitted it and it went well apart from the top linkage bolt size. The bolt is too small for the shock and due to the way the frame is braced they couldn’t just make a bigger hole. It looks ace in place though!

I went to an amazing local engineering shop to get them to make up a reducer for me. It was pure old school engineering no cnc stuff that I could see.

I then put the bike through another MOT which is failed again. ARRRGH! This time it was the front shocks which were misting slightly before are now leaking badly. Also the rear lights were an issue as the number plate light was too bright and caused problems.

So I started taking the front end apart to remove the shocks

Which is where I got stuck as I don’t have the correct tool to remove the front axle. I’ve got one side but not the other. I’ve ordered the tool which should be here this week.

I decided this was a good opportunity to move the key location so that I can tidy up the speedo area. I created a bracket to mount the key under the tank. Which I thought came out nice in the end.

Next I wanted to remove the old key hole to allow me to make a new speedo bracket.

It all is much tidier now and closer to my face.

Next up on the jobs I could do before tools arrive was to clean up the front brakes. As fork oil had leaked onto the pads and discs. I thought about cleaning the pads off, but decided it was far safer to replace them.

Finally I realised that the number plate light is not a legal requirement in the uk so it could go. This meant I could redo the rear bracket and make it simpler.

So I’m stuck waiting for tools before I can finally get it on the road. Fingers crossed the forks will be sorted this week.

The shock and mudguard arrive

Ok so I’ve mainly been waiting for parts to arrive. The main ones are the rear shock and the front mudguard. They both had to be custom ordered and manufactured which took a few weeks.

While I was waiting I made a new bracket for the number plate and rear lights.

I then fitted it to the bike

I was really happy with it. I may paint it in the future, but for the meantime I will leave it as bare aluminium.

Next I took delivery of the new mudguard. It’s from skidmarx and was reasonably priced. I tried finding one on ebay, but they were either the wrong colour or damaged.

Fitting the mudguard was a little fiddly, but I got there in the end. Its a different style to the previous one and I like it. Though one day in the future I’d like to make a super low profile small one.

I’m very happy with how it looks on the bike though.

Next up was waiting for the rear shock and shock linkage. The linkage I got from ebay and was a real pig to undo, but I managed it in the end. With flames and other heating!

Today the YSS shock finally arrived.

Making sure it’s ok Daddy.

Mmmmmmh pretty!

I’m going to get it fitted asap as I can then get riding hopefully very soon!

Fixes and more fixes

Well after the disaster of the MOT test I had lots to deal with. Most of it was minor, but some required thought and planning. The key issues are as follows:

1. The Rear shock linkage is terrible and needs doing correctly

2. The shock itself is old and knackered

3. The front mudguard is not one for this bike and isn’t secured correctly.

4. The rear light is playing up.

5. The brake torque arm is attached by a bolt not giving it movement

6. Footrest are insecure.

Just a few jobs then. I’ve got to work on these in turn.

1. The shock linkage was replaced at some point with sheet metal instead of the correct dogbones. I’ve got a second hand shock linkage from eBay which will need fitting. You can see the issue below. I didn’t catch it as I didn’t look under the bike right there. It’s passed mot’s before which is worrying!

2. The shock is very old now and finding a better alternative was the best plan. I’ve search around to find a suitable second hand alternative, without decent success. So I bit the bullet and ordered a new shock. Its a YSS one and was well priced. They are making it for me now. Once it’s arrived I can fit it and the dogbones.

3. The mudguard was easy. It can pass the mot without one. So I removed it. I’ve ordered a replacement from Skidmarx. That will arrive in a couple of weeks. In the meantime it looks much cooler without the mudguard!

4. The rear light was an odd one, I swore it was working, but I was wrong. It’s not lighting up properly. I tried loads of things, but I worked out in the end that the light had broken. Very annoying. I thought about getting a replacement, but my faith in that lasting wasn’t good. So I looked for alternatives. In the end I found a combined indicators/brake/rear light system that is in a tiny cnc strip.

The seller was in Australia and it arrived in less than a week! I was amazed. I started testing it to make sure it worked.

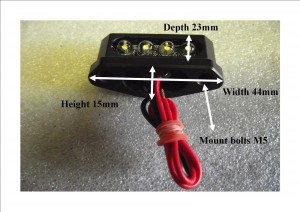

As this light sticks to the number plate I also needed a number plate light. I found a tiny cnc number plate light on ebay and had to have it.

With both of these changes I had to remake the number plate bracket. I’ve spent the last couple of days knocking this up, It needs the light mounting to the number plate, but it’s close to being done.

5. The bolt was a right bodge job and needed me to source the proper torque bushing. I managed to find a new one which was good. I need to fit it tomorrow.

6. The footrests were using too small a bolt as the eyes of my cnc footpegs were smaller than the originals. I drilled out the the holes and fixed a larger bolt in place. You can also see the new oil cap I found going cheap on ebay.

Rain rain stay away

Well the weather forecast was not good so I decided to take matters in to my own hands.

It was a great idea as it allowed me to work on the wiring in the dry all day.

I spent several hours rewiring the loom and putting new connectors on. It was a real pain to do, but quite rewarding.

There is still more sleeving to do, but I ran out of my loom harness tape. So it will need to be finished when the new order arrives.

I did get a chance to wire it all in and test things like the new speedo.

I also tested the new headlamp, but discovered a problem. The side light ring was working, but not the main or dipped beam arggggh!!! I was hoping what I had done already would have fixed that, but no.

I started attacking the loom with a multimeter to try trace the issue back to it’s source. I ended up back at the fuse box and this seemed to be where the issue was. However the fuse was fine which confused me. It took me a moment to work out that the issue was actually the connectors being old and rusty.

So I decided to replace the fuse box and see if that solved the issues.

That would be a big fat yes!

I was so relieved as I’ve been trying to sort that issue out for some time. I even considered getting someone else to look at it, but I was determined that I could find out the issue.

So there is not much more I need to do before getting it MOT’d and back on the road:

1. Finish the loom wiring

2. Setup the speedo and finish the wiring of that.

3. Get the tank back on and filled with fuel.

4. Get her started!

With some good weather and orders arriving swiftly I hope to get that done in the next week or two.

Wiring , headlamp and indicators

I’ve started work on the cable spaghetti, it’s not pleasant work, but who said it would be all fun!.

First job of the week so far was to sleeve the two indicators so that the cables would be less obvious. I also did the same to the new headlamp.

Next up I fitted them back on the bike. I was originally going to reuse the bolts from before, but in the end I decided to get some new ones so that I could use an allen key instead of a socket wrench. It makes fitting the indicators much easier. I also moved them to the bottom bolt so that the cable runs underneath and is more hidden.

Next I stripped back the loom so that I could see what is going on and if I can make any improvements.

There were a few iffy connections which I am working through. If I get good weather this weekend I will try to finish the wiring loom changes.

Poker II Keyboard

I bought it before xmas as my first mechanical keyboard. It was originally a German ISO keyboard Cherry Red. I used a UK ISO PBT keycap set from ducky as a start. I then added some PBT doubleshot keycaps from Massdrop.

Other additions are my lego keycap that I made, a red aluminium spacebar and newly arrived today was a Holyoops backspace key.

I want to get a silver aluminium case and red cable from Pexonpcs then it will be finished… maybe

Headlight is on

Well I managed to get some more progress as the weather held off for 30mins. What I managed to get done was test mounting the headlight to make sure the brackets would work and they do!

First up some comparison shots of the old and new headlight. You can see just how much smaller the new one is.

I fitted the bracket off the bike first, to test it would work

Then I got it fitted to the bike. I love it! The pictures came out blurry unfortunately. I will have to take some better ones when I’m next out there.

Indicators Back on

Well the first hurdle is over. I’ve found a new mounting point for the indicators. I actually prefer them here instead of attached to the headlamp brackets. All I did was remove one of the fork bolts and make a bracket for the indicators on each side, using the bolt to attach them directly to the fork. I will need to dress the wiring and make that as hidden for each indicator next.

1: Remove the existing headlight and all wiring

2. Mock up some little brackets

4. Fit the indicators and see how it looks.

I also held the new headlamp in place to see how it looks on the bike.

The weather has now turned, so I’m not sure if I can get anything else done this weekend. I’d like to see to some of the wiring spaghetti if I can.

Headlight woes

Currently here is the problem. As it stands now there is all this mess of cabling in the current shell. Which is 7.5inches in diameter. As you can see it’s a total mess. I’ve cleaned up the speedo cabling, which was the worst of the looms, but there is still more that needs to be attacked.

The new headlight has a ring of LED’s around the outside just inside the shell casing. You can make them out in this picture here:

The whole thing is designed as a sealed unit that is not used to hide the cabling. So I think moving the cables back towards the tank area is the best plan of attack.

If the weathers not tipping it down, I will try to find some places to hide the wiring mess. I’m thinking maybe somewhere underneath the tank would be the best place. As it is hidden from view, but is close to where the existing wiring is. Maybe even in some kind of box to keep the connectors out of the worst of the weather.

Headlamp headaches

Well the headlight has turned up this morning and it looks great.

There is one thing that I wasn’t expecting. That is this headlamp has no space for the tons of wiring in the current one! Arggggh! Add to that the mounting system I’m currently using will not work as this uses smaller bolts and has no way for the indicator wires to go.

So I will have to think whether this can work, or do I have to modify it too heavily. I think I can work out moving the current wiring to somewhere else. The issue is where and how then do I mount the headlamp and indicators.